Liquid starters are used to start slip ring motors, electric motors and other drives.

To start a three-phase asynchronous motor from standstill, the torque generated by the current must be higher than the moment of inertia of the application. The required starting torque always depends on the application. It is influenced by factors such as mass, inertia and friction values as well as materials within the application.

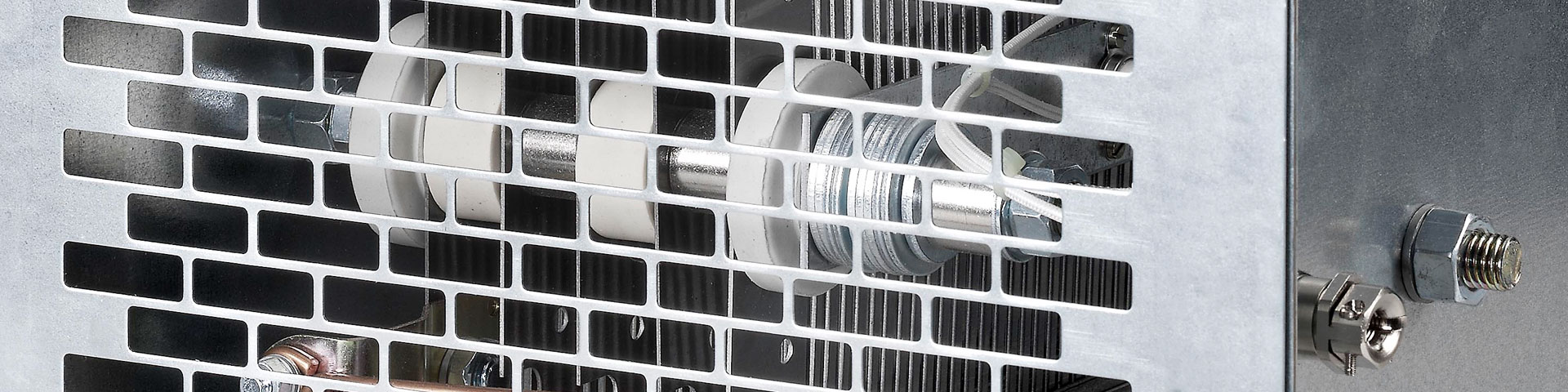

Starting resistors protect electrical components, motors and machines. Without a starting resistor, the starting current responsible for the movement would be more than 7 times the normal rated current. High starting currents lead to serious repercussions on the supply network and can cause damage to electrical components, motors and machines. Starting resistors are connected to the rotor circuit to start three-phase motors with slip ring rotors or DC motors and switched off again in stages.

In addition, the starting resistor enables a soft start, which protects electrical and mechanical components. Liquid starters limit the starting current and are preferably used where a very high starting torque is required. The robust design guarantees high operational reliability and a long service life in the most difficult environments.

A slip ring motor, also known as a three-phase asynchronous motor, consists of a stator and a rotor. The stator generates a rotating magnetic field, while the rotor performs the rotary movement. In the slip ring motor, the windings of the rotor are electrically connected via slip rings. When an external voltage is applied to the slip rings, a current flows through the rotor windings, generating a magnetic field and setting the rotor in motion. This enables the motor to be operated with variable torque and variable speed.

- Ball mills

- Autogenous mills

- Cement mills

- crushers

- Shredders

Liquid starters offer a number of advantages for industrial applications. One advantage is their ability to start motors smoothly. This means that the load on the motor and the connected mechanical components is minimized during start-up. This helps to extend the service life of the system and reduces wear. Another important aspect is the reduction of starting current peaks. By limiting the starting current, liquid starters help to relieve the electrical infrastructure and improve the power quality. As a result, unwanted voltage dips and faults in the grid can be avoided.

Liquid starters are extremely versatile and are used in a wide range of applications. They are particularly suitable when a controlled and smooth motor start is required. Such applications are often found in industries such as mining, power generation, water and waste water management, chemicals and petrochemicals. Liquid starters are used in pumps, fans, compressors, conveyors and other heavy machinery to ensure efficient and reliable start-up.

A notable advantage of liquid starters is their low maintenance requirement. Compared to conventional starting methods that use contactors or carbon brushes, liquid starters have fewer components that are susceptible to wear. This leads to longer maintenance intervals and reduces the need for regular maintenance interventions. This is particularly beneficial in industrial environments where minimal downtime and low maintenance costs are crucial.

Liquid starters can definitely be adapted to the specific requirements of an application. GINO AG offers various models with variable size, torque capacity and adjustment options. This allows you to select the most suitable liquid starter according to the requirements of your equipment. The flexibility in terms of adaptability makes liquid starters an attractive option for a wide range of applications.

Liquid starters contribute to energy efficiency by optimizing the starting process. By reducing starting current peaks, the load on the power grid is reduced, which in turn leads to improved power quality. This is particularly important in situations where multiple motors are started simultaneously, as it minimizes the risk of voltage dips and other grid disturbances. The ability of the liquid starters to precisely control the starting process helps to save energy and avoid unnecessary energy consumption.

Yes, liquid starters offer a range of protective functions that increase the safety of the systems. These protective functions include overload protection, blockage protection and phase failure protection. Overload protection prevents the motor from being damaged under excessive load. Blockage protection detects blockages in the system and prevents damage caused by uncontrolled operation. Phase failure protection protects the motor against damage that could be caused by a phase failure in the power grid.