Ribbon-wound resistors

Ribbon-wound resistors use ribbons or sheet strips as resistor conductors. Depending on the design, ribbon-wound resistors can be broken down by wave-pattern “folded” ribbons or spot-welded ribbons connected in series as individual strips. With this method, high-performance resistors with low-resistance are obtained. The advantage of ribbons is that large surfaces can be achieved at a comparably low material weight, the former being crucial for the heat transfer at high continuous ratings.

Regarding the ribbon design, two types are possible:

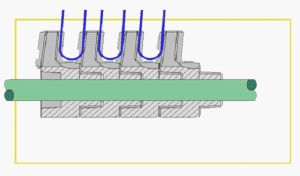

Continuously folded ribbons with terminals at both ends.

Picture: 3PQ4 design, continuously folded ribbon, mounted on special plug-in ceramic supports, suited for permanent temperatures of up to 850 °C. Patented by Siemens.

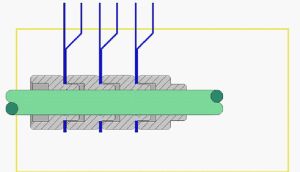

Individual ribbons, inter-connected (mostly by spot welding).

Picture: 6GN1 design, spot-welded ribbons mounted on support brackets with ceramic insulators.

Both techniques have their special features and offer specific advantages over the other one. The optimum design for a given application is dependent on the specific requirements and design conditions. The selection and design require long years of experience and are performed at GINO in collaboration with the experts from our system development function.

Christoph Becker

Phone: +49 (0) 228 98986-41

Email: christoph.becker@gino.de

David Jansen

Phone: +49 (0) 228 98986-935

Email: david.jansen@gino.de

Thomas Tindel

Phone: +49 (0) 228 98986-940

Email: thomas.tindel@gino.de

Jan Gaertner

Phone: +49 (0) 228 98986-71

Email: jan.gaertner@gino.de