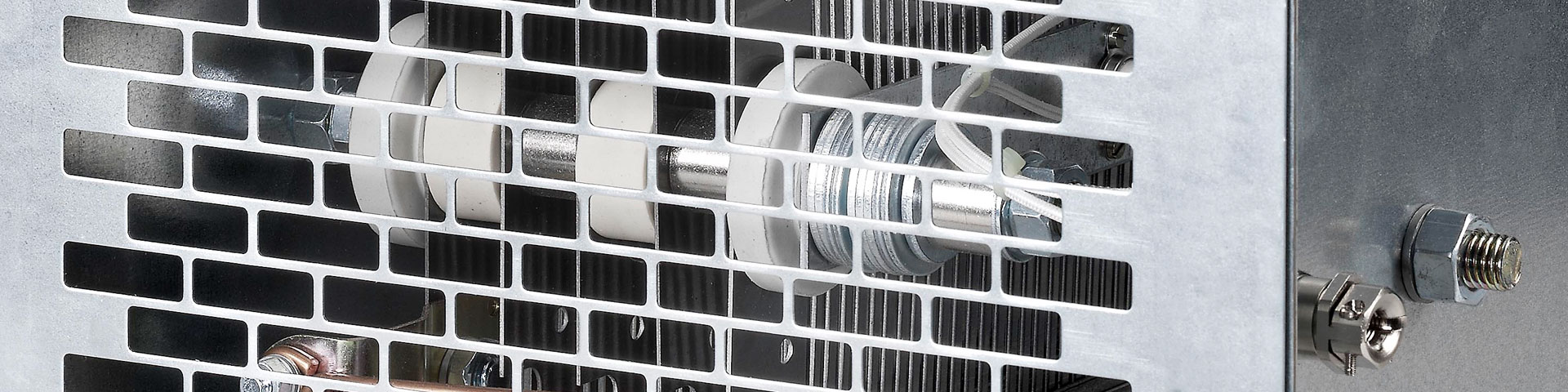

GINO braking resistors take on the excess energy of a driven motor thereby slowing it down. The driven motor takes on the role of a generator. The current direction and moment reverse and the generator tries to counter-act the drive forces, i.e. it brakes. Modern drive technology now only operates with three-phase motors. A slip ring motor with power supply from the grid with a reversed field takes the role of a generator, supplies its energy to the resistors in the rotor circuit and is thereby slowed down. However, state-of-the-art drive technology almost exclusively uses squirrel cage motors. Where the speed is to be controlled, static frequency converters are used which, in a first step, convert the line voltage to direct voltage (d.c. link voltage) and then into a three-phase output voltage with variable frequency. The motor speed follows the frequency at the outlet of the frequency converter. If the frequency is smaller than the actual speed, the motor becomes oversynchronous and turns into a generator that returns the excess energy. The energy is taken on by a braking resistor installed in the intermediate circuit. This may occur in the form of brief surges or, as in the case of a train driving downhill, of energy acting for a longer period of time. The braking resistor must be capable of taking on both brief surges and the specified continuous load. In principle, all designs are suited for application as braking resistor. For smaller drives, wire-wound resistors are often used while larger drives require cast iron, steel grid or ribbon-wound resistors.

go back

You are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information