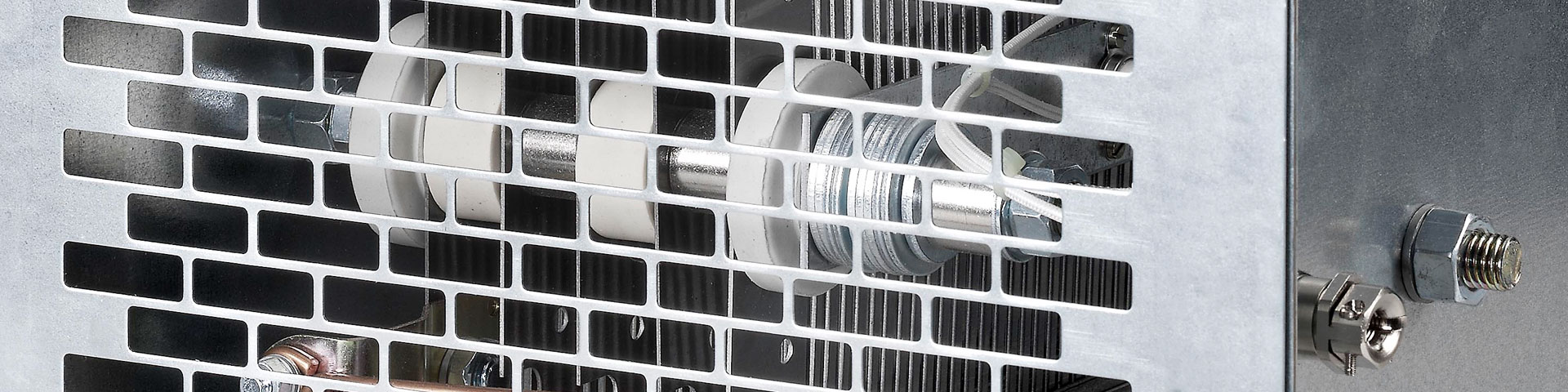

Thermal resistors are either resistors embedded in a heat sink casing (mostly made from aluminum) or resistors that have to be mounted on a separate heat sink to reach their full nominal capacity. The advantages of thermal resistors lie in their compact design and high protection class so that most additional measures to protect the unit from unintentional touching of current-carrying elements can be omitted. The resistance conductor is embedded in an insulating compound (quartz sand, ceramic powder) or directly applied on a ceramic support, which in turn is installed in an aluminum casing with cooling fins. The casing can also be cooled directly with forced air or water thus resulting in very compact designs. Due to the good heat transition between resistor conductor and compound, high conductor loads are possible. However, the mostly poor impulse resistance attributable to the small resistor conductor mass must be considered. In the range from 0,1 to 2…3 s, here too the energy has to be stored in the resistor conductor since, even in case of good heat transfer, little heat is transferred to the compound within a short period of time. Thermal resistors in general require the same surface for heat transfer that would also be required by an air-cooled wire-wound or ribbon-wound resistor with the same surface temperature. The advantage of thermal resistors lies in the fact that erection plates or control cabinet walls can equally be used as erection surface and thus as cooling surfaces.